There are two kinds of car engines – internal combustion engines and external combustion engines. Steam engines are external combustion engines invented in the Industrial Revolution in which an external heat source is required for the combustion of fuel. On the other hand, the internal combustion engine was developed in the late eighteenth century in which an external heat source is not required by the engine. Examples of such engines are petrol engines and diesel engines. These are more efficient than steam engines and are smaller as well.

The technology in the engine is continuously developing due to which now hybrid or electric cars are also being used. In order to create combustion, most automobiles make use of gasoline or other petroleum products.

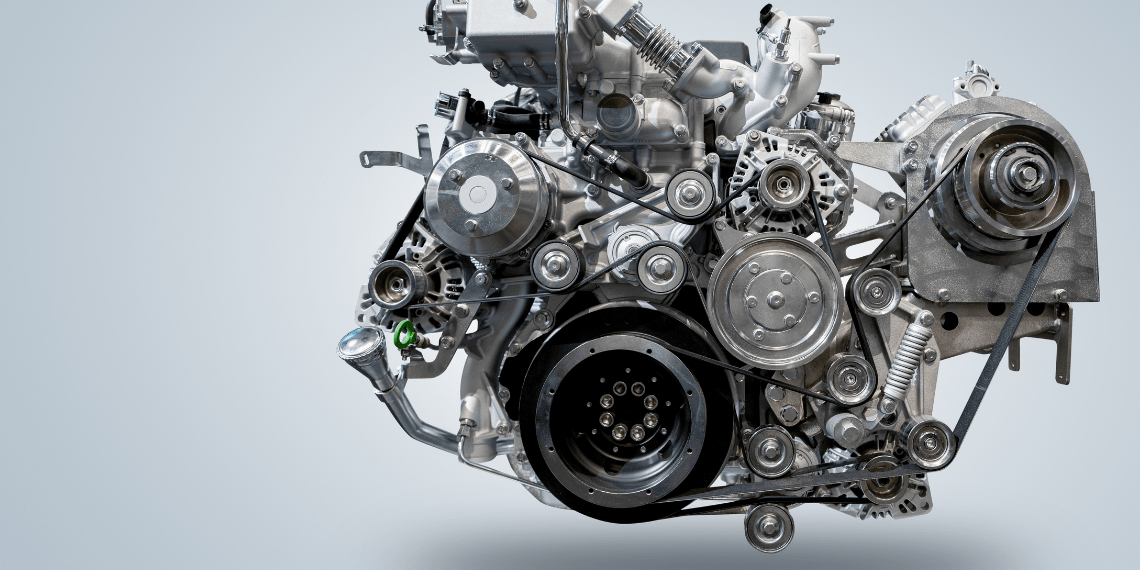

Internal Combustion Engine

Most of the private vehicles make use of gasoline and there are more gasoline engines all over the world due to the continuous increase in the number of automobiles sold.

In a gasoline engine, the combustion of gasoline and air takes place in a metal cylinder that slides and retreats. The engine works when the available volume of the gases in the cylinder is reduced with the movement of the piston. The piston leads to a change in the pressure and the engine moves when the gases expand. In internal combustion engines, chemical energy is converted into kinetic energy.

The main components of an internal combustion engine are the air intake valve, exhaust valve, spark plug, fuel injector, piston, cylinder, connecting rod, and crankshaft. In cars, more than one cylinder is present, it can be four, six, or eight cylinders.

One cylinder is mainly present in lawn mowers.

The cylinders are arranged in one of the three ways in a multi-cylinder engine. These can be inline, flat, or V arrangements.

There are different advantages and disadvantages of these configurations related to manufacturing cost, smoothness, and shape characteristics.

The function of the spark plug is to provide the spark for ignition of the air-fuel mixture which helps in combustion. A piston is present inside the cylinder which moves up and down. It is a piece of metal in a cylindrical shape.

There are two valves, intake and exhaust valves which open at the correct time to let in the fuel-air mixture and to let it out. In order to seal the combustion chamber, both valves are closed at the time of compression and combustion. To make a sliding seal between the outer edge of the piston and the inner edge of the cylinder, piston rings are present which help in preventing the entry of fuel-air mixture into the combustion chamber during compression and combustion.

Also, they help in preventing leakage of the oil into the combustion area which otherwise could be lost due to burning. The piston is connected to the crankshaft with the help of connecting rod which can rotate at both ends. As the piston moves, its angle needs to be changed which can be done with the rotation of the connecting rod. The function of the crankshaft is to turn the piston up and down. The sump is present around the crankshaft which contains some amount of oil.

These engines are mainly four-stroke engines in which there are four stages or strokes- intake, compression, combustion, and exhaust.

Intake stroke – This stage starts with the turning of the crankshaft due to which the piston is pulled down and out of the cylinder. With this, the valve opens and a mixture of air and gasoline is introduced into the cylinder.

Compression stroke – In this stage, the piston moves back due to which the space for the fuel and air mixture is compressed. Thus, the pressure in the space increases. When there is the full insertion of the piston in the cylinder, space reduces further due to which a spark is created by the spark plug and the mixture is ignited.

Combustion stroke – Within a short period of time, a large amount of heat is produced in the fuel-air mixture due to ignition. With this, pressure increases further and the piston moves out of the cylinder. The crankshaft is turned due to the release of the piston leading to insertion of the next piston and the process continues.

Exhaust stroke – This is the final stage in which burned gas is thrown out of the cylinder through the exhaust valve and the exhaust pipe.

In this type of engine, at a particular time, each cylinder is at one of the four stages due to which there is a continuous movement of the engine.

Diesel Engine – As compared to gasoline engines, the working of a diesel engine is different. It is mainly used in larger vehicles like ships and buses.

In this engine, only air is compressed and so, the compression ratio becomes high and thus, diesel engines are more efficient. Also, it has got a higher average thermodynamic efficiency of 45% as compared to a gasoline engine which has 30% efficiency. Apart from this, energy in diesel is 11% more as compared to the same amount of gasoline. Due to these reasons, diesel when used as a fuel experiences an advantage.

There is no requirement for an ignition system in the diesel engines due to which the breaking down of parts is less. Also, more torque is produced by diesel engines for a longer time due to which heavy load vehicles are suitable for such engines.

Electric vehicles – The engines in these vehicles are similar to the gasoline engines as the chemical energy is converted into kinetic energy in them. The only difference is that, instead of fuel, the input in electric vehicles is electricity.

Hybrid vehicles – These vehicles make use of gasoline and electric motors both to produce power. The gas-only engines are larger and less efficient as compared to the gasoline counterparts. Hybrid cars make use of electric motors in regenerative braking, automatic start, and electric motor drive.